Welcome to the ADVANTEC Group

The future of mining and tunnel construction lies not in our hands, but in our machines!

Even though our home, Germany's Ruhr Valley, has changed, we know that there's still plenty of life in the mining and tunnel construction industries. The challenges have merely become more technical, demanding, efficiency-related and globalised. Therefore, here at ADVANTEC we have positioned ourselves to not merely dig new paths in the mining and tunnel construction industries, but rather to actively shape the future of the industry.

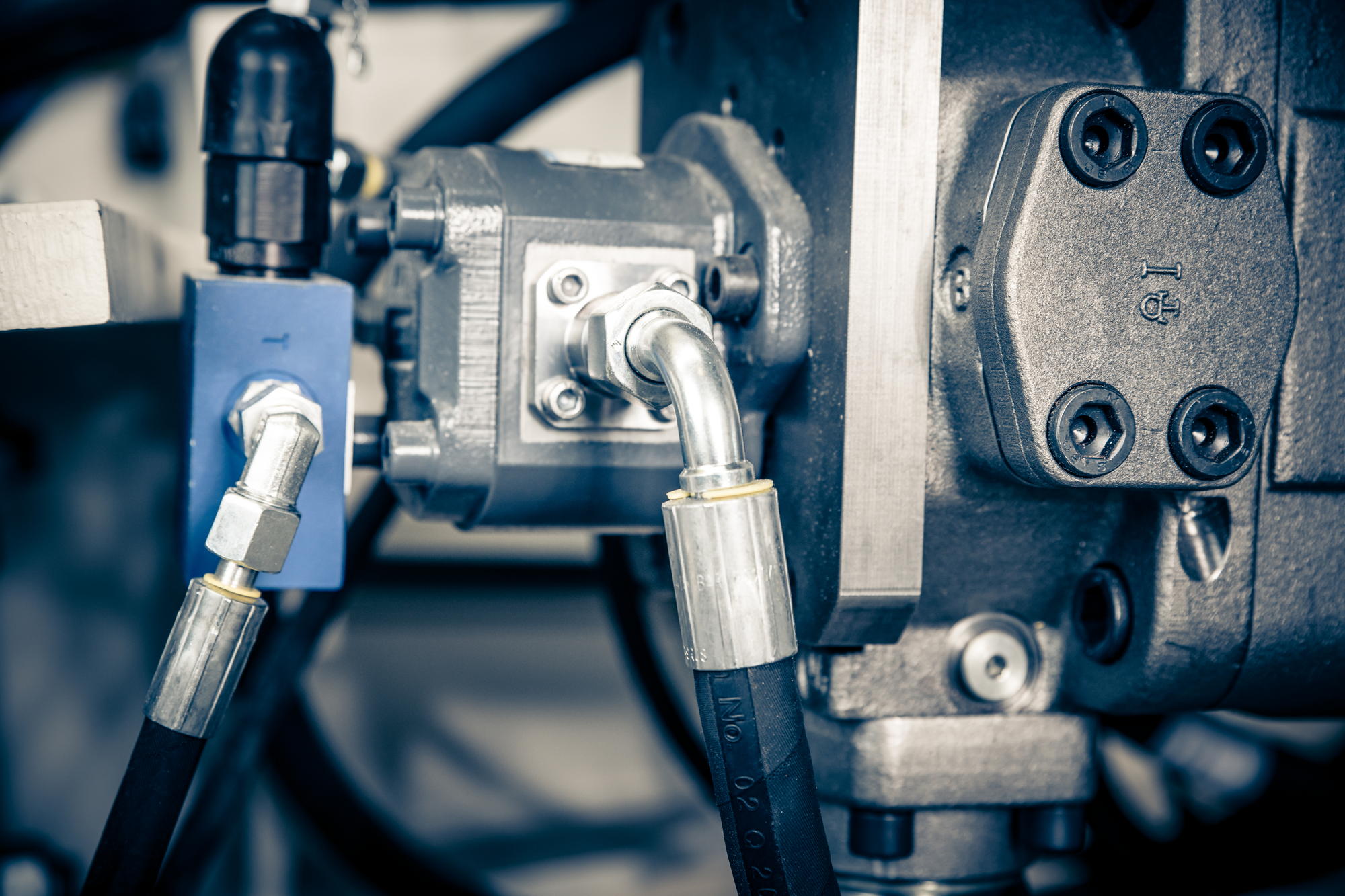

In our factory in the heart of the Ruhr Valley, we are continuously developing and refining our machines, meaning we are always at least the length of a cutting head in front of the competition. At the same time, in important areas we solely deploy our own quality products. For example, the hydraulics, which we custom manufacture on our premises. Or with our industrial servicing, where we are in action worldwide, directly helping our customers on site.

Thanks to our group of companies being based on these main pillars, we can guarantee our customers that in future, there is one thing that will not change: our quality promise!